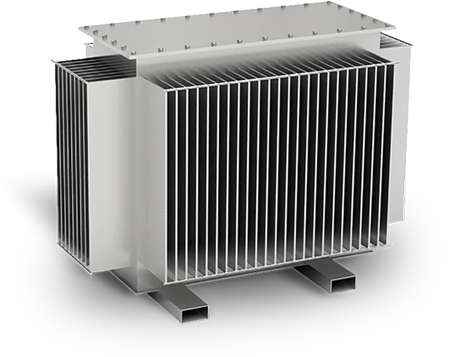

MS CORRUGATED WALL PANELS / TANKS

MS Corrugated Wall Panels (Finwalls) has substituted the use of traditional transformer tanks that with radiator. It serves as a tank body which acts as an excellent Heat Exchanger.

FEATURES

HIGH

EFFICENCY

Cooling

LESS

OIL

REQUIRED

LESS

STEEL

USED

COST

EFFECTIVE

SMALLER

FOOTPRINT

STRONG

CONSTRUCTION

ABOUT

INTRODUCTION

Established in 2009, Prowess Engineering Private Limited is the leading manufacturer of Corrugated Wall Panels / Fin Wall type of radiators in India. Prowess Engineering is one of the first few companies in India to set up fully automated Corrugation lines (2 lines) to serve various Transformer OEMs catering to the Power & Distribution Transformer Industry.

In the year 2009, PEPL formed a joint venture alliance with Thai Maxwell Electric Company Limited from Thailand (TME). PEPL’s joint venture with TME, one of Thailand’s leading electric power products and pneumatic products manufacturers, strengthens and enhances our expertise through technical and management collaboration. The product lines of Prowess are MS Corrugated Wall Panels / Fin Walls for Distribution and Power Transformers, and MS Corrugated Transformer Tanks.

The products manufactured by Prowess adhere to the most stringent standards in manufacturing and quality. PEPL has qualified personnel’s who have had rich experience working with some of the leading engineering companies in India.

LINE OF ARRAY

PRODUCTS

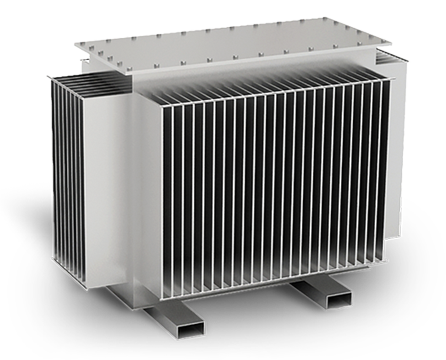

MS CORRUGATED / FIN WALLS TANK & COVERS

Fin walls tank are manufactured according to customer designs and relevant welding procedures.

Maximum fin height is 1600 mm.

Maximum fin height is 1600 mm.

Maximum dimensions are 4000 mm x 4000 mm x 4000 mm.

Maximum dimensions are 4000 mm x 4000 mm x 4000 mm.

Maximum total weight is 7500 Kg.

Maximum total weight is 7500 Kg.

ADVANTAGES

Compact in size - Transformers with corrugated walls are smaller than transformers with radiators.

Compact in size - Transformers with corrugated walls are smaller than transformers with radiators.

Improved heat dissipation - the role of fins is to increase the surface of the tank, which is in contact with the cooling air. Due to the temperature

Improved heat dissipation - the role of fins is to increase the surface of the tank, which is in contact with the cooling air. Due to the temperature

rise of the windings under load, the oil temperature also rises. The hot oil rises, meets the top cover and goes down into the fins where it is cooled by the air rising up between the fins. Required heat dissipation can be achieved by varying the number of corrugations and the depths height of corrugations.

Due to vertical Oil Channel greater stability is achieved.

Due to vertical Oil Channel greater stability is achieved.

The fins have sufficient degree of elasticity to absorb the expansion in volume of the liquid, due to the heating of the cooling medium at the same

The fins have sufficient degree of elasticity to absorb the expansion in volume of the liquid, due to the heating of the cooling medium at the same

time it provides for a larger dissipating surface to cool the same medium.

No blockage of oil flow into the fins. Blockage of oil is possible in pressed steel type radiator due to possible closing of header pipe connection on

No blockage of oil flow into the fins. Blockage of oil is possible in pressed steel type radiator due to possible closing of header pipe connection on

the tank walls, unlike corrugated tanks.

Oil cleaning is easier and economical.

Atheistic Appeal is higher than the traditional transformer tank.

Oil cleaning is easier and economical.

Atheistic Appeal is higher than the traditional transformer tank.

The Transportation cost is lower due to reduction in weight and overall dimensions.

The Transportation cost is lower due to reduction in weight and overall dimensions.

The requirement of space for installation of the Transformer is lower

The requirement of space for installation of the Transformer is lower

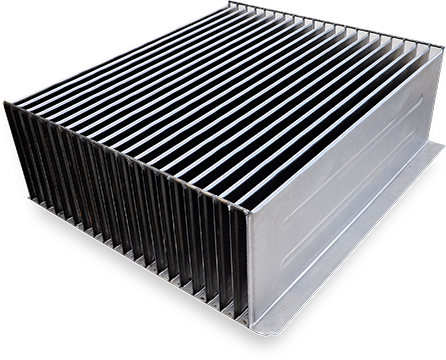

MS CORRUGATED WALL PANEL / TRANSFORMER FIN WALLS/ FIN WALL TYPE RADIATOR

The corrugated wall panel / fin walls are directly welded to the transformer tank. Besides the obvious advantage of reduction on the overall dimension of the transformers, the thermo power wastage is lower and the flow of oil does not become sluggish hence the efficiency of the radiators is better. This in the long term improves the usable life of the transformer and maintenance cost is lowered.

ADVANTAGES

1. Potential for saving in materials - Reduction > 30%

2. Reduction in the weight of the radiators - Reduction > 30 %

3. Reduction in the overall dimension of the - About 50% volumetric reductions.

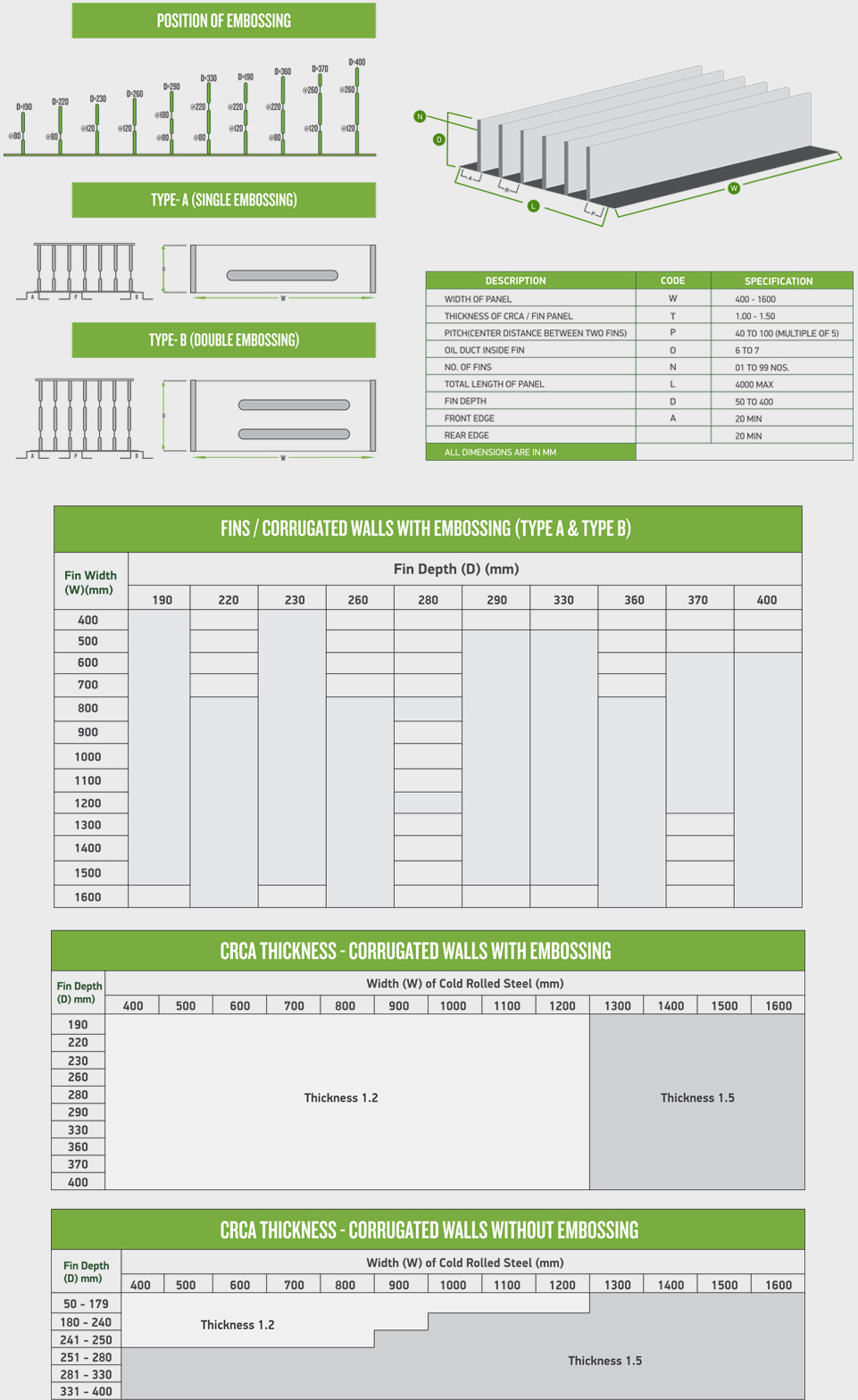

General : Finwalls are designed to be used in the transformer tanks up to 10 MVA to let the cool fluid to complete a circulation pattern and to be

General : Finwalls are designed to be used in the transformer tanks up to 10 MVA to let the cool fluid to complete a circulation pattern and to be

cooled by transferring heat through the fins to the ambient air.

Material : Cold rolled steel according to EN 10130 / IS 513

Material : Cold rolled steel according to EN 10130 / IS 513

Fin Width : 400 mm to 1600 mm

Fin Width : 400 mm to 1600 mm

Fin Depth : 50 mm to 400 mm

Fin Depth : 50 mm to 400 mm

Edge Bending : 45 & 90 Degree Upward & Downward

Edge Bending : 45 & 90 Degree Upward & Downward

Embossing : Available upon customer request

Embossing : Available upon customer request

Spot Welding : Available upon customer request

Spot Welding : Available upon customer request

Stiffener : Available in Φ8 mm & Φ 10mm

Stiffener : Available in Φ8 mm & Φ 10mm

Quality : Leakage control by UV light against dye penetrant

Quality : Leakage control by UV light against dye penetrant

TECHNICAL DETAILS FOR CORRUGATED WALL PANELS / FIN WALLS

CONTACT

REGISTERED OFFICE AND PLANT

GAT No. 262/263/264,

Nanekarwadi, Pune - Nashik Highway,

Chakan, Pune - 410 501, INDIA.

+91 92255 32520 / +91 92255 32519

REACH US

FOR ENQUIRY

E-BROCHURE

DOWNLOAD PDF

For specific information about our products please fill out the following enquiry form:

( * Mandatory Field )